The pickling line mainly uses mechanical and chemical effects to remove the oxide scale and dirt on the surface of the strip steel coils coming from the hot continuous rolling mill to obtain a clean steel plate. This plays a key role in the metallurgical field before cold rolling production.

Worldwide, about 3/4 of the steel coils produced by hot-rolled strip mills will be provided to continuous steel strip pickling units for processing. Among them, 98% of the strip pickling units use horizontal type. Continuous pickling unit. Therefore, it is crucial to maximize the potential of the unit. Because of this, the role of electrical transmission is even more self-evident because it can determine whether the entire equipment can operate stably.

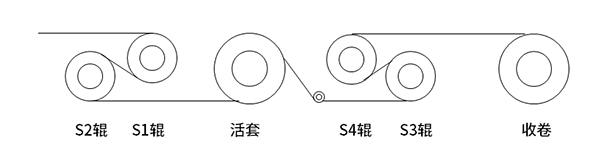

Pickling line process flow

In short, the process of the pickling line is: feeding → uncoiling → scale breaking and traction → cutting → welding → storage sleeve → pickling tank 1 → pickling tank 2 → squeeze dry → clean → passivation → squeeze dry → Cutting → Rewinding → Discharging.

The process requires transmission control with logic control, synchronous control, and tension control to ensure that the steel strip runs at a constant speed during the pickling process in the pickling tank, maintains the tension of each section of material, and collects it into rolls.

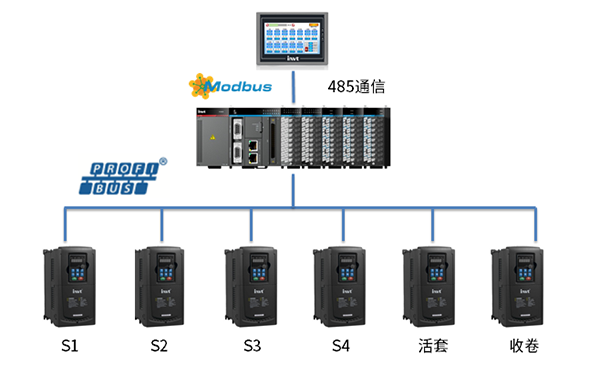

Equipment control diagram

INVT solution

According to the transmission and system control requirements of the pickling line, INVT proposed an overall system solution of HMI+PLC+Goodrive35 series high-performance closed-loop vector VFD, using the optimal control method for each step of the process.

S1 roller - transmission roller, INVT GD35 closed-loop vector control VFD is used, which adopts closed-loop speed mode and has high speed control accuracy. At the same time, the VFD is controlled by DP communication bus to pull incoming materials from the pickling tank in front to ensure that the steel strip runs at a uniform speed in the pickling tank.

S2 roller - tension control roller, INVT GD35 closed-loop vector control VFD is used, which adopts closed-loop torque mode and high torque control accuracy. It uses DP communication to control the tension between S1 roller and S2 roller to prevent material slippage.

Looper- material storage mechanism, using INVT GD35 VFD, space voltage vector mode, DP communication, one-to-multi mode, one VFD drives 12 motors. The function is to store materials, ensure constant speed of the entire line, and prevent the steel strip from being in the pickling tank for different times, resulting in inconsistent thickness.

S3 roller - transmission roller, INVT GD35 closed-loop vector control VFD is used, which adopts closed-loop speed mode and has high speed control accuracy. At the same time, the VFD also adopts DP communication bus mode to control the incoming material of the traction looper.

S4 roller - tension control roller, INVT GD35 closed-loop vector control VFD is used, which adopts closed-loop torque mode and high torque control accuracy. It uses DP communication to control the tension between S3 roller and S4 roller to prevent material slippage.

Winding roller, it uses INVT GD35-07 tension-specific VFD and DP communication to control the tension between the S4 roller and the winding line speed to keep the winding line speed constant. The maximum winding diameter is 2000mm. The automatic calculation function of the winding diameter ensures constant tension and winding shaping.

Electrical control scheme diagram

High degree of automation to ensure safety and stability

INVT Goodrive35 series high-performance closed-loop vector VFD is widely used in pickling line equipment. Its excellent overload capacity and dynamic response speed can ensure safe and stable operation of the equipment.

Advantages of INVT overall solution

1. It has a high degree of automation. The system adopts Profibus-DP bus control, the communication rate reaches 1.5M, and the response speed is fast. Since a large number of A/D and D/A modules are omitted, the requirements for PLC hardware are greatly reduced, and high software development costs are saved.

2. The HMI interface is beautiful and easy to operate. It can monitor various process parameters and abnormal phenomenon alarms and faults during the production process in real time.

3. INVT VFDs have multiple control methods, open/closed loop vector control, vectored VF control technology, and their excellent overload capacity and low-frequency and high-torque characteristics can fully ensure the stable operation of equipment under heavy load conditions.

4. The winding process uses INVT GD35-07 tension-specific VFD, which has open and closed loop tension control, automatic roll diameter calculation and automatic roll changing functions. The PLC only completes simple logic control and main speed processing. A large number of tension control and calculations are performed by VFD. It is automatically completed inside the machine, installation and debugging are simple and easy, and it can ensure constant tension winding of steel coils and can fully meet various winding occasions.

Since 2009, INVT has entered the field of metallurgical engineering transmission by establishing strategic partnerships with industry leaders to break the monopoly and technical barriers of foreign brands in the metallurgical industry. After more than ten years of development, INVT has appeared in every key link of more and more metallurgical enterprises. In the future, INVT will continue to adhere to "customer-centric" and provide a steady stream of strong products, solutions and service guarantees for metallurgical enterprises.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.